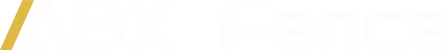

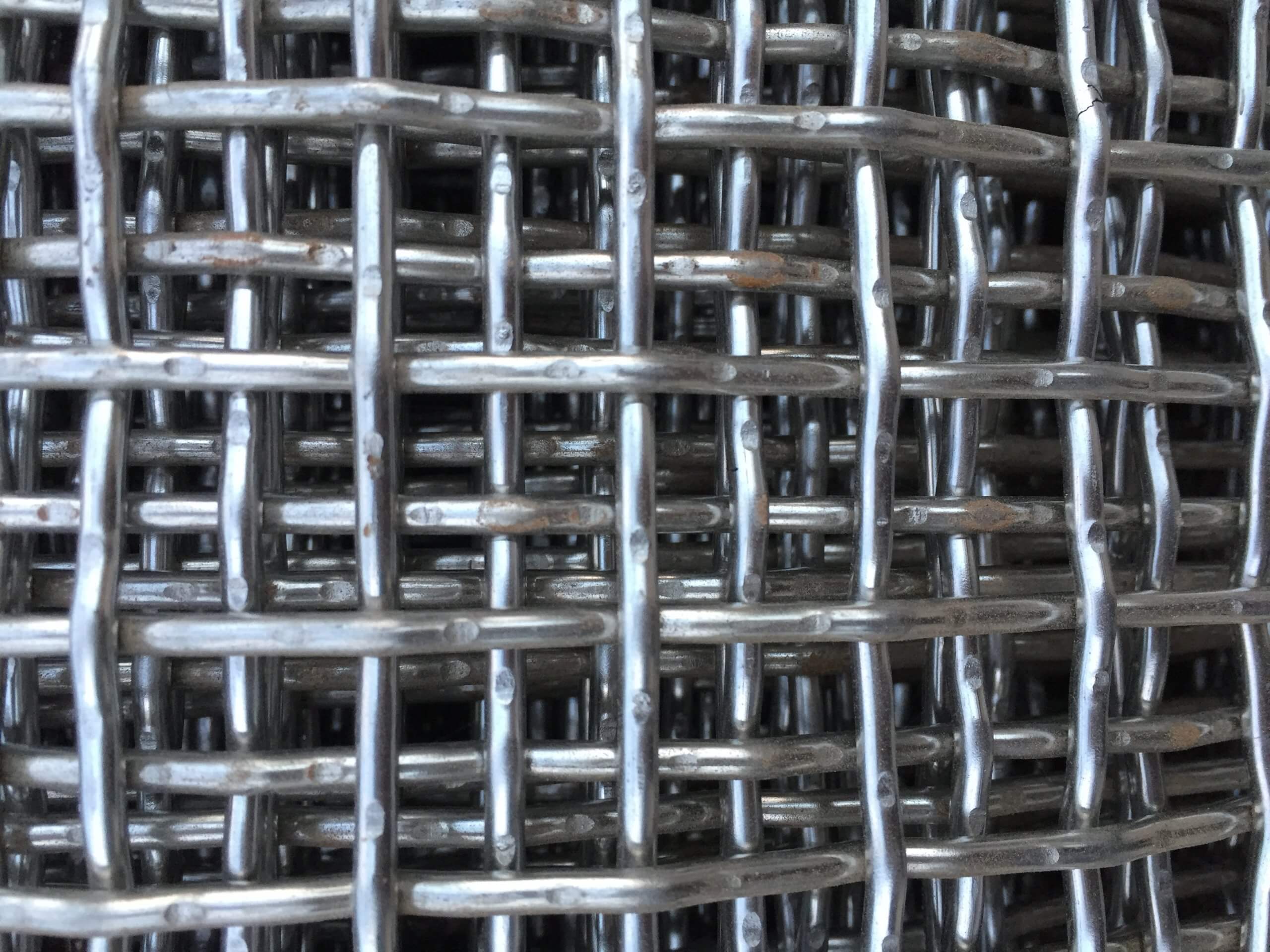

Crimped Weave Mesh

Crimped weave mesh is made from top quality manufacturing in Ferrous & Non-Ferrous Metal.

It has different weaving approach, such as the double kinky, level leading kinky, intermediate kinky and also lock crimped. The kinky woven wire mesh has square opening and rectangle opening, which has different wire diameters and also applications. The pre-crimped weaving technique can assure the precise open area as well as make the structure security and also smooth. The weave wire mesh has numerous applications.

The heavy-duty woven wire towel can utilize as shaking screen in the mining, Прочная изогнутая проволочная ткань может использоваться в качестве вибрирующего дисплея в горнодобывающей промышленности., crusher and other industries. The light crimped wire mesh with thinner wire size as well as little opening dimension can used as Grilled mesh fit together for the equipment as well as stairs.

Сетка из волнистой проволоки

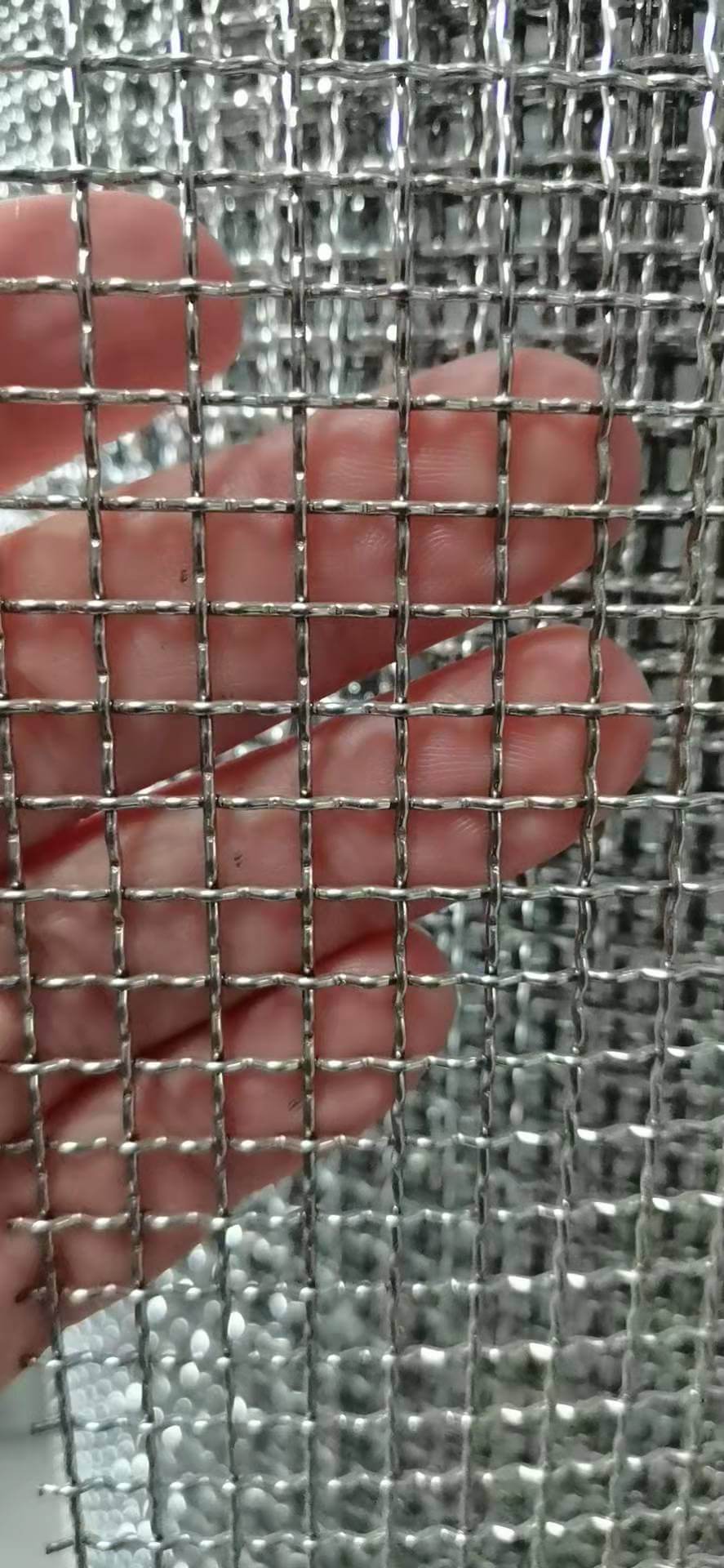

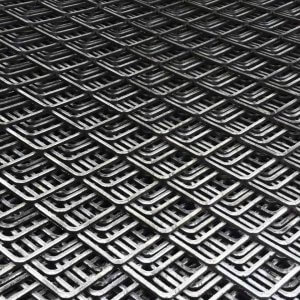

Flat top crimp

Flat top crimp, also called pushed weave, made from round as well as profiled ordinary weave wire. All the mesh knuckles being on the underside. The framework is very hefty as well as durable. The smooth surface is the attribute of the weaving technique. This framework can allow the materials to move extra easily over the screen. It widely made use of in the shaking screen.

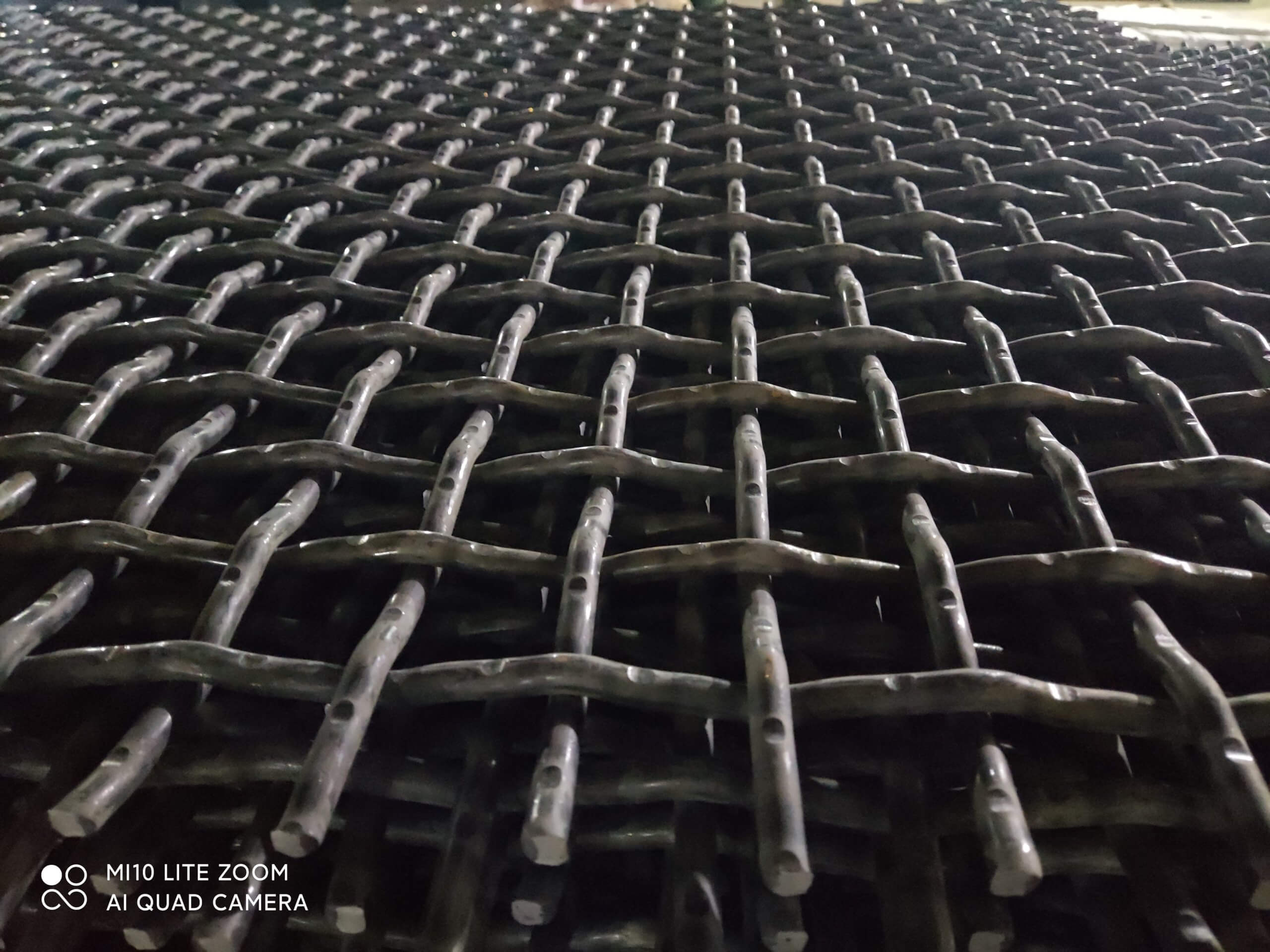

Lock crimp

Lock crimp is a refinement of the intermediate crimped. It can secure the wire at their setting with pressed at each side of the elevated wire. This structure can include the stability of the kinky woven wire mesh.

Double crimp

Double crimp additionally called ordinary weave. Different from the intermediate kinky, both the warp wire and also weft wire are woven straight by straight wire. We can get an inflexible building and construction with uniformly kink in warp and weft wire. The cords are under crimped as well as sprung together therefore giving a limited mesh. This is made use of generally with lighter wires to ensure stress in a light screen.

Features of Stainless steel:

- Superb formability and also machinability

- Has a higher resistance to intergranular attacks.

- Both SS 304 L as well as SS 316 L quality is a trustworthy alternative

- Quickly customized right into any intricate designs without any special tools.

- Handling and also machining of fine wire mesh are likewise very easy.

- Discover applications in a vast array of commercial industries and also commercial applications.

- For sieve mining.