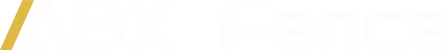

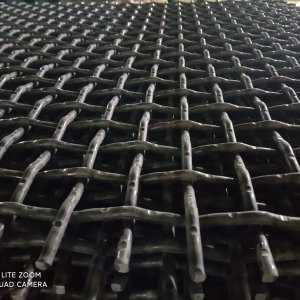

Crimped wire Mesh

Crimped wire mesh made of metal wire by plain woven, and molded in advance, so make the steel wire in both instructions in the appropriate setting, thus ensuring mesh dimension the uniform of the wire screen.Crimped wire mesh has good structure as well as solid long lasting.

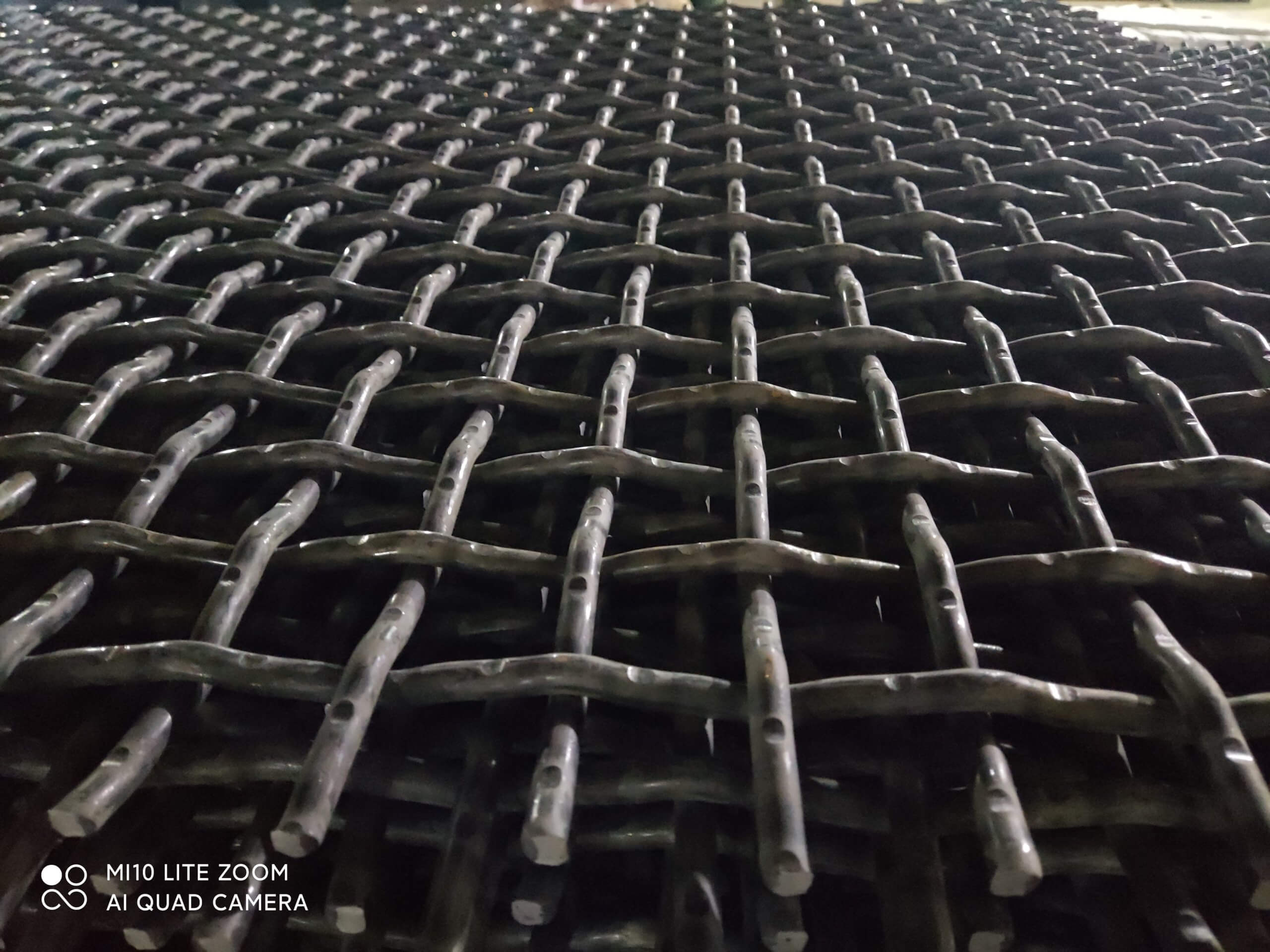

Firstly, woven Wire Mesh made of galvanized wire, stainless steel wire or carbon steel wire.

Crimped wire mesh offers excellent dimensional toughness and also security, terrific resistance to abrasion, uniform openings and also excellent anti-corrosion. Therefore it is generally utilized as mining sieve screen, quarry as well as various other commercial areas as sieving, grading and also separating screening materials.

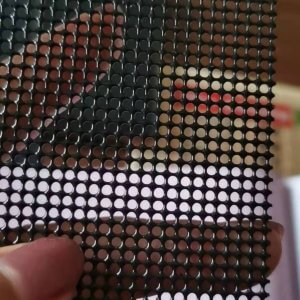

Woven mesh :

Woven mesh made of the opening forms of square mesh or rectangle-shaped mesh. Rectangle-shaped opening crimped mesh offers typically for heavy type crimped mesh for mining sieve screen, coal plant or pig reproduction which require huge filling ability.

Attributes of Crimped Mesh: High safety, lovely, sturdy, rust resistance

Add rigidity and assure precise mesh

A lot more wearing surface and also longer put on life

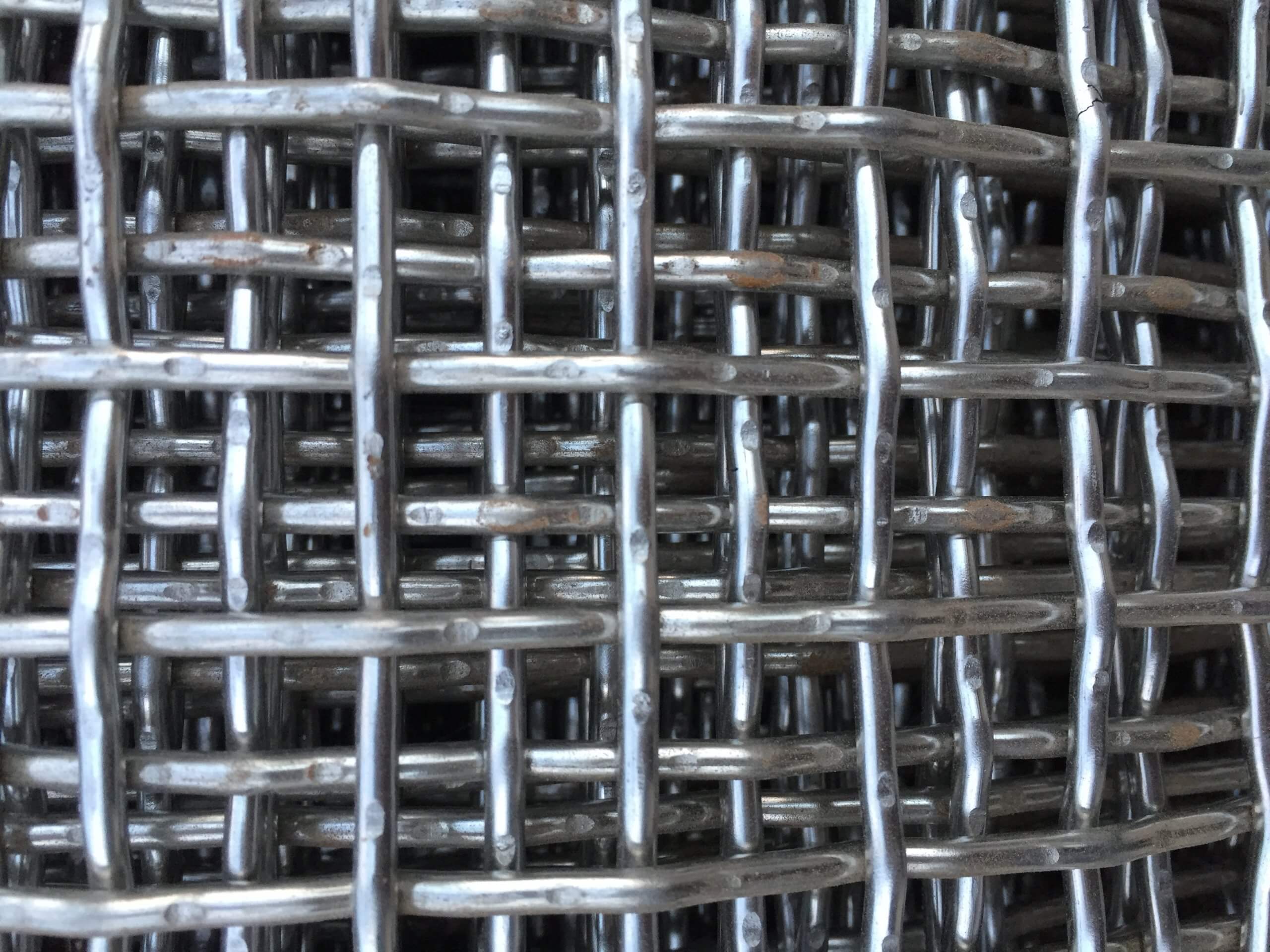

Specification:

Wire diameter:0.55 mm-5.0 mm.

Aperture size:0.72 -100 mm.

Harmonize counts:1 -20 mesh.

Form in rolls or panels:1 m X 15 m, 1.5 m X 15 m, 2.0 m X 20 m. etc.

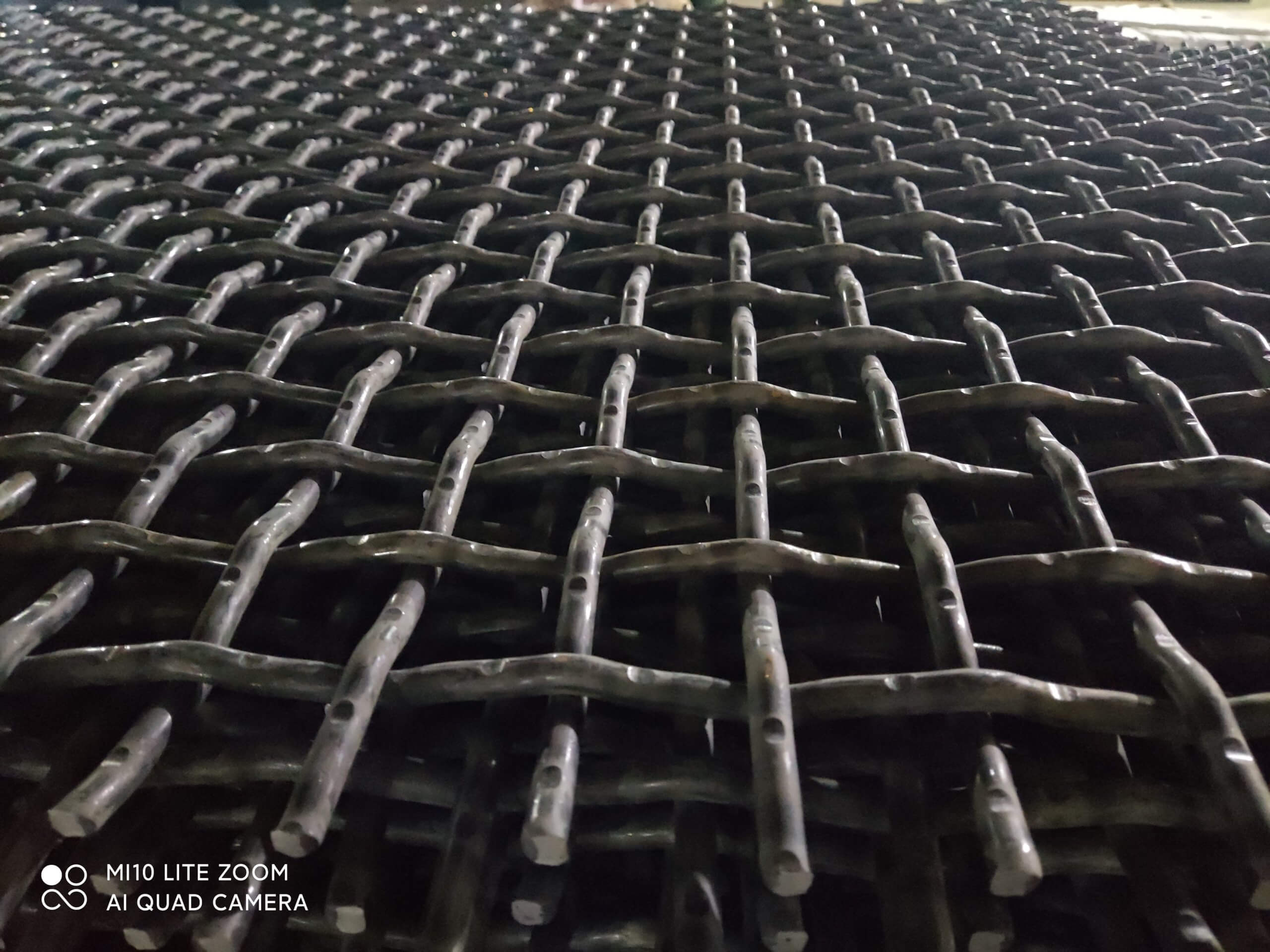

Crimped Wire MeshApplication:

Steel vibrating wire mesh offers excellent dimensional toughness and resistance abrasion, so generally used quarry screen in mine.

For instance, it is widely utilized in mining, coal manufacturing facility, petroleum, chemical, building, safety fence, product packaging webs, outdoor grill netting, vibrating screen, food machinery, cooking tools, mine sieving, etc.Some materials of galvanized and stainless steel woven mesh are for roasting of flour food and also meat.

Weave style:

1. Plain Crimped Weaving

2. Intermediate Crimped Weaving

3. Lock Crimped Weaving

4. Top flat Crimped Weave

5. Count off Crimped Weave

6. Raw Edge Vs Selvage Edge

Crimped wire mesh has excellent toughness ,used for quarry and other industrial fields for sieving, grading and separating screen materials.